|

AMacss™ ... World Class Automated Floor Router

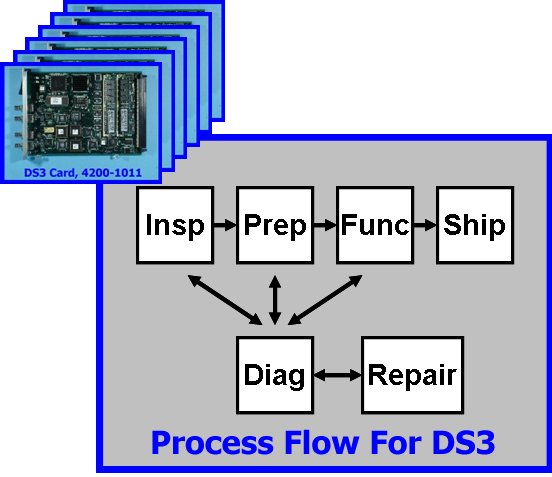

The Manufacturing Test Process Is Complicated

Complex electronics products are fabricated, inspected, programmed,

tested, diagnosed, repaired and upgraded at different, defined steps in

the manufacturing process. Some of these process steps are mandatory

and must be executed in the correct order before a unit may ship to a

customer.

Different kinds of units may take different routes through the process.

If a unit fails a step, it may need to retested, diagnosed, or

repaired. Many hundreds of units may be "in process" at any moment.

Time may be running out as the quarter comes to a close. The operators

may be inexperienced. In short, much can go wrong without the proper

automatic control and management!

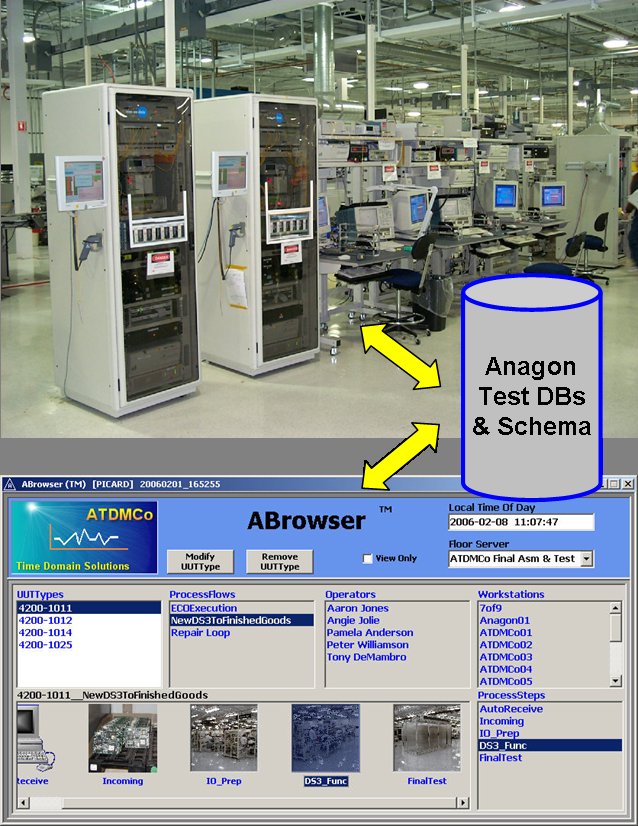

AMacss™ Models The Manufacturing Floor And Gives You Control!

Based on years of practical manufacturing experience, Anagon has

developed a powerful and flexible data model that can accurately

describe your manufacturing floor. Your part numbers, test stations,

operators, process steps, and routing requirements are all mapped into

the AMacss™ system.

Before each unit is tested, the model is instantaneously read by all

test stations on the floor. In this way, AMacss™ ensures that each unit

is automatically routed to the correct step at the proper time. AMacss™

reduces floor chaos by providing real time control and management of

the floor, automatically and continuously!

To Find Out More ...

AMacss™ is a state of the art routing system for the manufacturing

floor. For more information we invite you to download an AMacss™

presentation in Adobe

PDF®

|